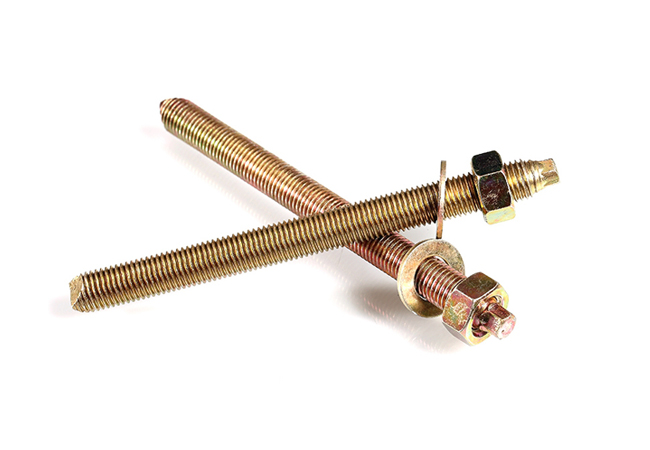

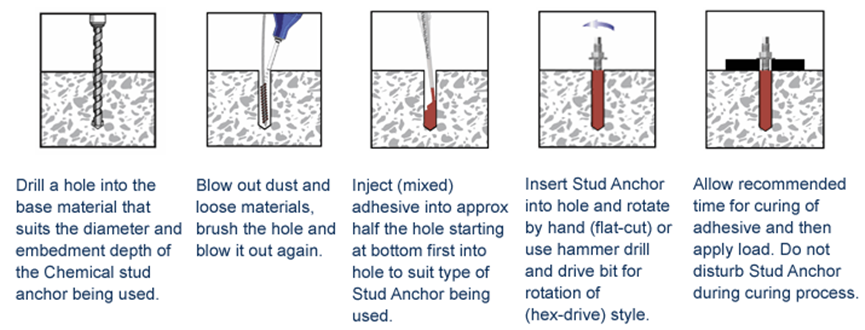

Chemical or resin anchors are generic terms relating to steel studs, bolts and anchorages which are bonded into a substrate, usually masonry and concrete, using a resin based adhesive system.

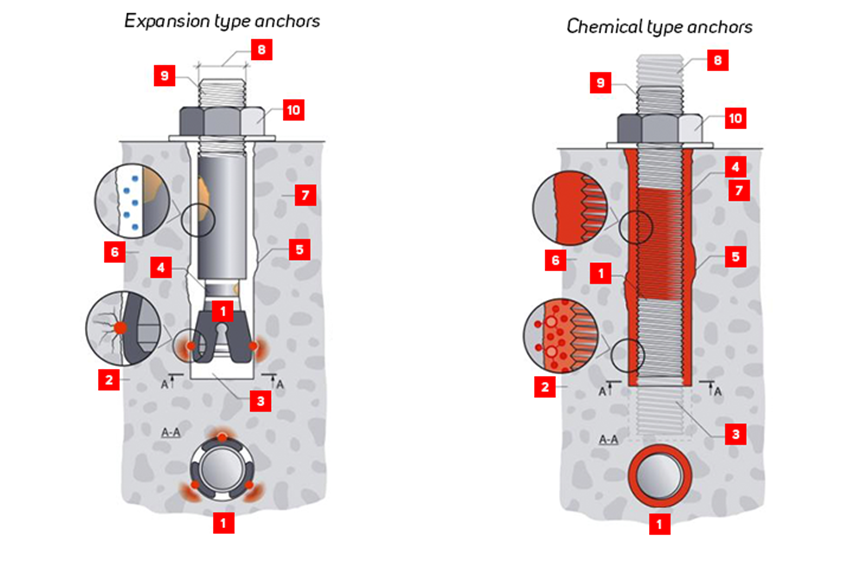

Expansion type anchor

1. Load is concentrated at limited points

2. Stress is imparted directly into the substrate

3. Setting depths are limited

4. Metal anchors can contain unseen weak points

5. Not ideal for imperfect shaped holes

6. Prone to water ingress leading to corrosion.

7. Not suitable for softer base materials

8. Limited to stock sizes, length & diameter

9. Limited to stock steel grades

10. Excessive torque destroys the fixing

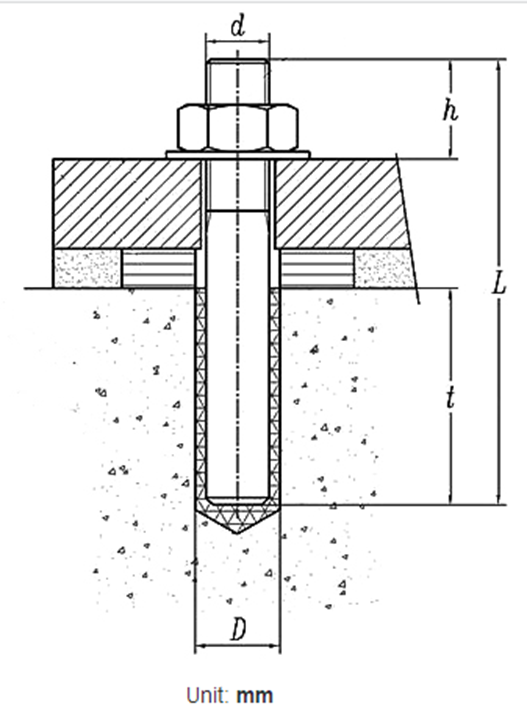

Chemical type anchor

Chemical type anchor

1. Load is applied to the length of the embedment2.

2. A molecular bond occurs, imparting no stress

3. Unlimited setting depths can be specified.

4 Threaded rod material has a higher stability.

5. Chemical injection can fill imperfect drilled holes.

6. Protects the fixing from corrosion.

7. Suitable for all substrates

8. Large array of sizes available.

9. High grades of steel can be specified

10. Increased torque loads can be applied.

| Screw Thread d | M12 | M16 | M20 | M24 | M30 | M36 | M42 | M48 | M56 | M64 | ||

| D | 15 | 20 | 25 | 30 | 36 | 42 | 48 | 55 | 62 | 72 | ||

| t | 110 | 125 | 170 | 210 | 280 | 300 | 350 | 400 | 500 | 600 | ||

| h | 30 | 35 | 40 | 50 | 60 | 80 | 90 | 100 | 120 | 130 | ||

| per unit≈kg | L=100mm | 0.113 | 0.205 | 0.336 | 0.505 | 0.857 | 1.32 | 1.94 | 2.76 | 3.87 | 5.1 | |

| Every additional 10 mm | 0.009 | 0.016 | 0.025 | 0.036 | 0.055 | 0.08 | 0.109 | 0.142 | 0.193 | 0.252 | ||