What's the best way to determine the clamp size you'll need? Simply measure the outside diameter of your hose with the fitting installed. Some clamps accommodate a range of sizes, so be sure the size you need falls in the middle of that range.

General Purpose Worm-Drive Clamps for Firm Hose and Tube

So easy to install, it's no wonder these are the most frequently used style of hose clamps. Clamps are for firm plastic and rubber hose and tube. Do not exceed the maximum torque or clamps may be damaged.

Zinc-plated steel has fair corrosion resistance.

410 stainless steel offers good corrosion resistance.

301 and 305 stainless steel have very good corrosion resistance.

316 stainless steel has excellent corrosion resistance.

Note: When choosing a clamp, measure the outside diameter of your hose or tube with the fitting installed.

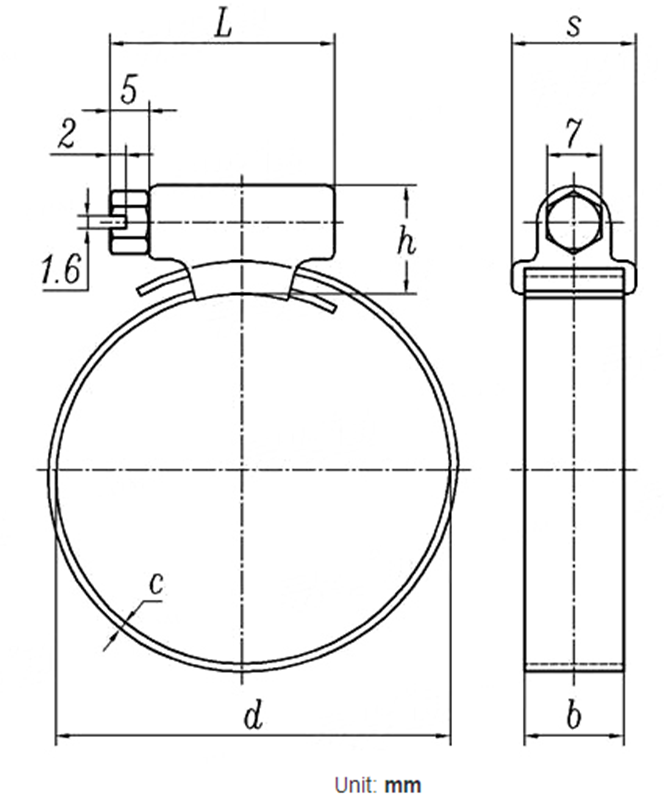

| Nominal Diameter d | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 60 | 70 | |||

| d | Jaw range | min | 8 | 10 | 12 | 16 | 20 | 25 | 32 | 40 | 50 | |

| max | 12 | 16 | 20 | 25 | 32 | 40 | 50 | 60 | 70 | |||

| c | max | 0.45~0.8 | 0.45~0.8 | 0.45~0.8 | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | ||

| L | max | 20 | 20 | 20 | 25 | 25 | 29 | 29 | 29 | 33 | ||

| b | max | 10 | 10 | 10 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | ||

| s | max | 12 | 12 | 12 | 16 | 16 | 16 | 16 | 16 | 16 | ||

| h | max | 12 | 12 | 12 | 14 | 14 | 14 | 14 | 14 | 14 | ||

| Nominal Diameter d | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | |||

| d | Jaw range | min | 60 | 70 | 80 | 90 | 100 | 110 | 120 | 130 | 140 | |

| max | 80 | 90 | 100 | 110 | 120 | 130 | 140 | 150 | 160 | |||

| c | max | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | 0.5~1 | ||

| L | max | 33 | 33 | 33 | 33 | 33 | 33 | 33 | 33 | 33 | ||

| b | max | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | 12.8 | ||

| s | max | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | 16 | ||

| h | max | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | 14 | ||