Parallel pin can reduce the stress created on welded tube joints when compared to tapered rolling.

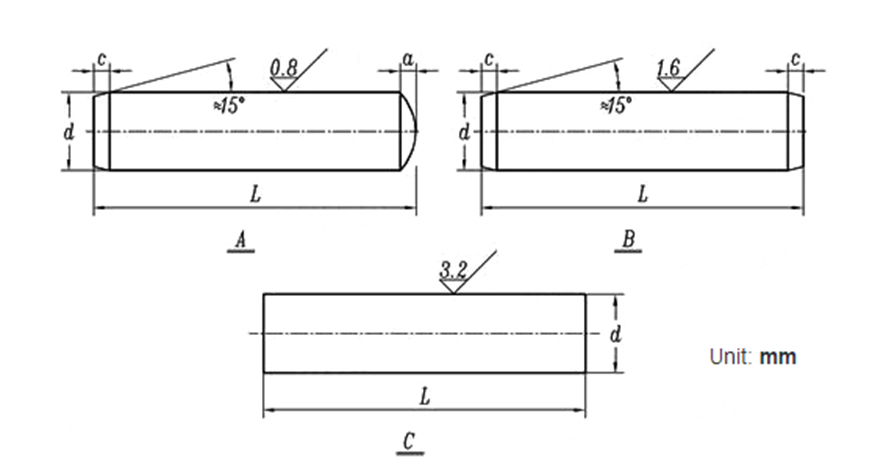

ISO Metric Dowel Pins per DIN EN ISO8734

Dowel Pins per. DIN EN ISO 8734. Parallel pins, of hardened steel and martensitico stainless steel Table gives the characteristics of parallel pins (dowel pins) of steel, through hardened or case hardened and martensitic stainless steel with nominal diameters, d, from1 mm to 20 mm inclusive

| Screw Thread d | Φ0.6 | Φ0.8 | Φ1 | Φ1.2 | Φ1.5 | Φ1.6 | Φ2 | Φ2.5 | Φ3 | Φ4 | Φ5 | |||

| d | Type A (m6) | Max. | 0.608 | 0.808 | 1.008 | 1.208 | 1.508 | 1.608 | 2.008 | 2.508 | 3.008 | 4.012 | 5.012 | |

| Min. | 0.602 | 0.802 | 1.002 | 1.202 | 1.502 | 1.602 | 2.002 | 2.502 | 3.002 | 4.004 | 5.004 | |||

| Type B (h8) | Max. | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | ||

| Min. | 0.586 | 0.786 | 0.986 | 1.186 | 1.486 | 1.586 | 1.986 | 2.486 | 2.986 | 3.982 | 4.982 | |||

| Type C (h11) | Max. | 0.6 | 0.8 | 1 | 1.2 | 1.5 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | ||

| Min. | 0.54 | 0.74 | 0.94 | 1.14 | 1.44 | 1.54 | 1.94 | 2.44 | 2.94 | 3.925 | 4.925 | |||

| α | ≈ | 0.08 | 0.1 | 0.12 | 0.16 | 0.2 | 0.2 | 0.25 | 0.3 | 0.4 | 0.5 | 0.63 | ||

| c | ≈ | 0.12 | 0.16 | 0.2 | 0.25 | 0.3 | 0.3 | 0.35 | 0.4 | 0.5 | 0.63 | 0.8 | ||

| Screw Thread d | Φ6 | Φ8 | Φ10 | Φ12 | Φ13 | Φ16 | Φ20 | Φ25 | Φ30 | Φ40 | Φ50 | |||

| d | Type A (m6) | Max. | 6.012 | 8.015 | 10.015 | 12.018 | 13.018 | 16.018 | 20.021 | 25.021 | 30.021 | 30.025 | 50.025 | |

| Min. | 6.004 | 8.006 | 10.006 | 12.007 | 13.007 | 16.007 | 20.008 | 25.008 | 30.008 | 40.009 | 50.009 | |||

| Type B (h8) | Max. | 6 | 8 | 10 | 12 | 13 | 16 | 20 | 25 | 30 | 40 | 50 | ||

| Min. | 5.982 | 7.978 | 9.978 | 11.973 | 12.973 | 15.973 | 19.967 | 24.967 | 29.967 | 39.961 | 49.961 | |||

| Type C (h11) | Max. | 6 | 8 | 10 | 12 | 13 | 16 | 20 | 25 | 30 | 40 | 50 | ||

| Min. | 5.925 | 7.91 | 9.91 | 11.89 | 12.89 | 15.89 | 19.87 | 24.87 | 29.87 | 39.84 | 49.84 | |||

| α | ≈ | 0.8 | 1 | 1.2 | 1.6 | 1.6 | 2 | 2.5 | 3 | 4 | 5 | 6.3 | ||

| c | ≈ | 1.2 | 1.6 | 2 | 2.5 | 2.5 | 3 | 3.5 | 4 | 5 | 6.3 | 8 | ||