To fasten the rivet, the end of the shank is impacted, pressed or spun after the rivet has been inserted into a work-piece. A solid head is formed (upset) to create the clinched head of the rivet. When impact or press clinched, the force required to form the clinched head of the rivet swells the entire shank of the rivet to completely fill the work-piece hole. Swelling of the shank occurs most by the clinched head end of the rivet. Spun/orbital/radial rivet clinches require less tonnage to form than impact or pressed rivets; therefore, do not have the same shank swelling capability. Pre-punched or drilled work-piece holes are required for use on most solid rivet applications.

WHY USE SOLID RIVETS?

High speed assembly. Rivets feed automatically in impact Rivet Machines that cycle in approximately 3/10th of a second

Material grain flow structure of solid rivets, along with the shank swelling during assembly, creates the strongest riveted joint. High shear strength values

Permanent fastener that cannot be removed without destroying one of the rivet heads

Inexpensive alternative to threaded fasteners

Ease of joint inspection

Virtually no scrap is produced during the manufacturing process

Easily adapted for automation

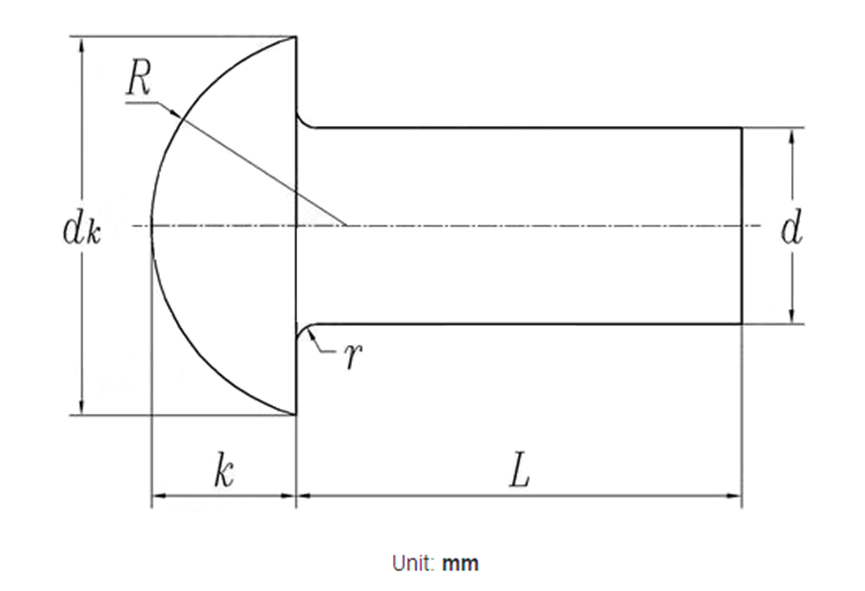

| Nominal Diameter d | Φ0.6 | Φ0.8 | Φ1 | (Φ1.2) | Φ1.4 | (Φ1.6) | Φ2 | Φ2.5 | Φ3 | ||||||

| d | max | 0.64 | 0.84 | 1.06 | 1.26 | 1.46 | 1.66 | 2.06 | 2.56 | 3.06 | |||||

| min | 0.56 | 0.76 | 0.94 | 1.14 | 1.34 | 1.54 | 1.94 | 2.44 | 2.94 | ||||||

| dk | max | 1.3 | 1.6 | 2 | 2.3 | 2.7 | 3.2 | 3.74 | 4.84 | 5.54 | |||||

| min | 0.9 | 1.2 | 1.6 | 1.9 | 2.3 | 2.8 | 3.26 | 4.36 | 5.06 | ||||||

| k | max | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.2 | 1.4 | 1.8 | 2 | |||||

| min | 0.3 | 0.4 | 0.5 | 0.6 | 0.7 | 0.8 | 1 | 1.4 | 1.6 | ||||||

| R | 0.58 | 0.71 | 1 | 1.2 | 1.4 | 1.6 | 1.9 | 2.5 | 2.9 | ||||||

| r | max | 0.05 | 0.05 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 | |||||

| Nominal Diameter d | (Φ3.5) | Φ4 | Φ5 | Φ6 | Φ8 | Φ10 | Φ12 | (Φ14) | Φ16 | ||||||

| d | max | 3.58 | 4.08 | 5.08 | 6.08 | 8.1 | 10.1 | 12.12 | 14.12 | 16.12 | |||||

| min | 3.42 | 3.92 | 4.92 | 5.92 | 7.9 | 9.9 | 11.88 | 13.88 | 15.88 | ||||||

| dk | max | 6.59 | 7.39 | 9.09 | 11.35 | 14.35 | 17.35 | 21.42 | 24.42 | 29.42 | |||||

| min | 6.01 | 6.81 | 8.51 | 10.65 | 13.65 | 16.65 | 20.58 | 23.58 | 28.58 | ||||||

| k | max | 2.3 | 2.6 | 3.2 | 3.84 | 5.04 | 6.24 | 8.29 | 9.29 | 10.29 | |||||

| min | 1.9 | 2.2 | 2.8 | 3.36 | 4.56 | 5.76 | 7.71 | 8.71 | 9.71 | ||||||

| R | 3.1 | 3.8 | 4.7 | 6 | 8 | 9 | 11 | 12.5 | 15.5 | ||||||

| r | max | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.3 | 0.4 | 0.4 | 0.4 | |||||

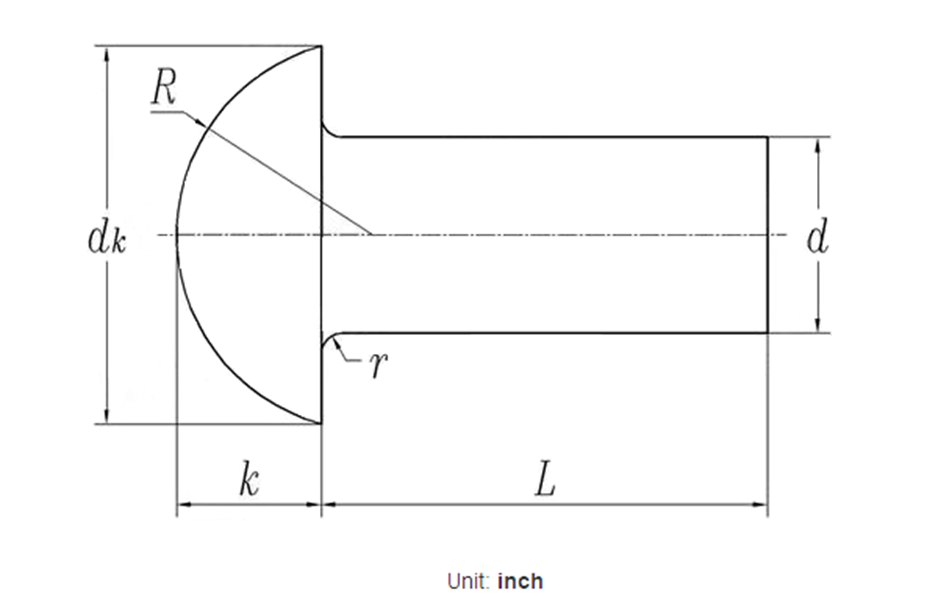

| Screw Thread d | 1/16 | 3/32 | 1/8 | 5/32 | 3/16 | 7/32 | 1/4 | 9/32 | 5/16 | 11/32 | 3/8 | 13/32 | 7/16 | ||

| d | max | 0.064 | 0.096 | 0.13 | 0.158 | 0.191 | 0.222 | 0.253 | 0.285 | 0.316 | 0.348 | 0.38 | 0.411 | 0.443 | |

| min | 0.059 | 0.09 | 0.12 | 0.152 | 0.182 | 0.213 | 0.244 | 0.273 | 0.304 | 0.336 | 0.365 | 0.396 | 0.428 | ||

| dk | max | 0.122 | 0.182 | 0.24 | 0.29 | 0.348 | 0.405 | 0.46 | 0.518 | 0.572 | 0.63 | 0.684 | 0.743 | 0.798 | |

| min | 0.102 | 0.162 | 0.22 | 0.268 | 0.322 | 0.379 | 0.43 | 0.484 | 0.538 | 0.592 | 0.646 | 0.699 | 0.754 | ||

| k | max | 0.052 | 0.077 | 0.1 | 0.124 | 0.147 | 0.172 | 0.196 | 0.22 | 0.243 | 0.267 | 0.291 | 0.316 | 0.339 | |

| min | 0.042 | 0.065 | 0.09 | 0.11 | 0.133 | 0.158 | 0.18 | 0.202 | 0.225 | 0.247 | 0.271 | 0.294 | 0.317 | ||

| R | ≈ | 0.055 | 0.084 | 0.11 | 0.138 | 0.166 | 0.195 | 0.221 | 0.249 | 0.276 | 0.304 | 0.332 | 0.358 | 0.387 | |